Direct Tension Tester

一、 Overview

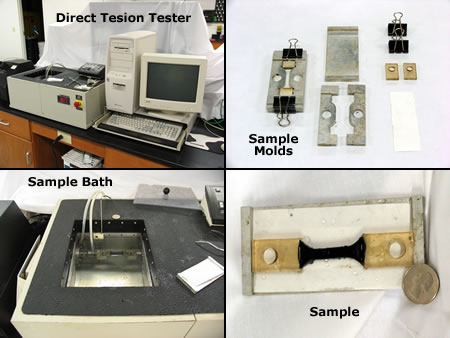

The Direct Tension Tester (DTT) test (see Figure 177, Figure 178) provides a measure of low temperature stiffness and relaxation properties of asphalt binders. These parameters give an indication of an asphalt binder’s ability to resist low temperature cracking. The DTT is used in combination with the BBR to determine an asphalt binder’s low temperature PG grade determination. As with other Superpave binder tests, the actual temperatures anticipated in the area where the asphalt binder will be placed determine the test temperatures used.

Figure 177: Direct Tension Tester.

Figure 177: Direct Tension Tester.

Figure 178: Direct tension tester.

Figure 178: Direct tension tester.

The basic DTT test measures the stress and strain at failure of a specimen of asphalt binder pulled apart at a constant rate of elongation. Test temperatures are such that the failure will be from brittle or brittle-ductile fracture. The test is of little use at temperatures where the specimen fails by ductile failure (stretches without breaking). DTT tests are conducted on PAV aged asphalt binder samples. The test is largely software controlled.

The standard DTT test is:

- AASHTO T 314: Determining the Fracture Properties of Asphalt Binder in Direct Tension (DT)

The Superpave PG binder specification involving the DTT is: - AASHTO PP 42: Determination of Low-Temperature Performance Grade (PG) of Asphalt Binders

二、 Background

As surrounding temperatures drop, pavements contract and build up internal stresses. If this contraction occurs fast enough the pavement may crack because it does not have time to relax these stresses. This type of crack, typically called a “thermal crack” (because of its cause) or “transverse crack” (because of its direction) (Figure 179) can result from either of two related mechanisms:

- 1. Single thermal cycle below the critical temperature. A single severe drop in temperature that causes stress to quickly build up to a critical point that causes cracking. This is called “single-event low temperature cracking” and the particular temperature associated with these critical stresses is called the “critical temperature”.

- 2. Thermal cycling above the critical temperature. Repeated thermal contraction and expansion that occurs above the critical temperature can cause stresses to build up and eventually cause cracking.

Figure 179: Thermal crack.

Figure 179: Thermal crack.

In both cases, the failure mechanism is essentially the same: thermal shrinkage initiates and propagates flaws or cracks in the asphalt binder portion of the HMA (Anderson and Dongre, 1995[1]). Ideally, an elaborate set of fracture mechanics tests would be used to fully characterize the nature of both crack initiation and propagation in an asphalt binder. However, these tests were deemed too sophisticated for routine specification testing and a simpler test was needed to indicate a threshold value stress or strain at which failure occurs due to rupture or excessive elongation. This threshold value represents a combination of crack initiation and propagation phases and can be determined using a constant rate of elongation tension test (Anderson and Dongre, 1995[1]).

The DTT is a test designed to measure asphalt binder low temperature fracture properties. In combination with the BBR, which is used to characterize the stress relaxation properties of an asphalt binder, these tests can give a good idea of whether or not an asphalt binder will crack at low temperatures.

DTT Logic

The DTT test is used to determine an asphalt binder’s failure stress and strain at low temperatures. These data, in combination with BBR data, are used to determine a critical cracking temperature of a pavement using the tested asphalt binder.

Testing Apparatus Development

Key choices when originally selecting the testing apparatus for the DTT, were based on the following ideas (Anderson and Dongre, 1995[1]):

- Sensitive testing apparatus. At low temperatures, asphalt binders are generally weak materials often requiring a strain of less than 1.0 percent and a stress less than 145 psi (1.0 MPa) to cause failure. These values are quite low and require a fairly sensitive testing apparatus capable of measuring strains on the order of 0.0008 to 0.008 inches (20 to 200 μm).

- Non-contact sample elongation measurement. Because failure was defined at such a low strain (1.0 percent). In most strain tests, elongation measurement is made with a strain gauge in contact with the sample. However, because of the low strain measurements required (failure is defined to occur at 1.0 percent strain), it was felt that contacting the sample would unduly affect results. When failure strains were less than about 3.0 percent, contact measurement errors became large (Anderson and Dongre, 1995[1]). Thus, a non-contact laser measurement technique was selected.

- Assisted gripping system. Gripping the sample at each end in order to elongate it presented problems because many gripping methods either slipped, loaded the sample eccentrically or fractured the cold asphalt binder sample. This led to the use of end inserts (Figure 4) that are molded with the sample.

- Sample length adequate for handling and testing. Long asphalt binder samples tend to break during handling while short ones do not offer an adequate section of constant tensile strain in the middle of the sample. A compromise between these two criteria led to an asphalt binder sample size of about 40 mm long by 6 mm thick.

Effective Gage Length Determination

In order to measure strain, the sample length before elongation must be compared to the sample length after elongation. Since only the center necked down portion of the sample is under nearly constant strain, measurements should be taken on that portion only. Therefore, if the entire 1.57 inch (40 mm) sample length is used as the “before” measurement, the actual strain occurring in the 0.71 inch (18 mm) center section (Figure 3, “top dimensions”) is underestimated. However, it is not possible to establish reliable reference points for the laser measurement system to only measure the 0.71 inch (18 mm) center section. Therefore, an effective gage length of 1.33 inch (33.8 mm) is used as the “before” measurement since it results in a close approximation of the actual strain in the center 0.71 inch (18 mm) section.

Sample Aging

Because low temperature cracking is a phenomenon found mostly in older pavements, the test is run on the long-term aged residue from the PAV.

三、 Superceded Reporting Method

This section briefly describes the original reporting method for the DTT. This method has been superceded.

Originally, the DTT was only used if the asphalt binder did not pass the BBR test (e.g., creep stiffness was > 43,511 psi (300 MPa).

The idea was that a high creep stiffness BBR test value implies that the asphalt binder will possess high thermal stresses in cold weather as a result of shrinkage. The assumption is that the asphalt binder would crack because of these high thermal stresses. However, some asphalt binders (especially those modified with elastomers) may be able to stretch far enough without breaking that they can absorb these high thermal stresses without cracking. The DTT identifies these asphalt binders by measuring the strain at failure. Therefore, if the strain at failure is 1.0 percent or greater, the asphalt binder will likely absorb higher thermal stresses without cracking and the allowable creep stiffness specification could be raised to 600 MPa. The minimum m-value of 0.300 still had to be met.

Test Description

The following description is a brief summary of the test. It is not a complete procedure and should not be used to perform the test. The complete DTT test procedure can be found in:

AASHTO T 314: Determining the Fracture Properties of Asphalt Binder in Direct Tension (DT)

Summary

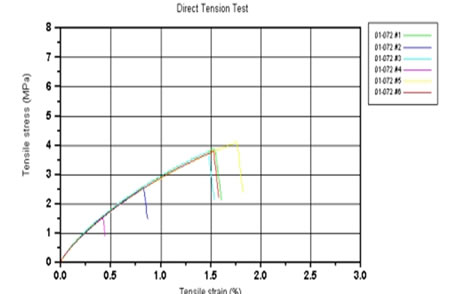

A sample of asphalt binder is molded into a necked shape for mounting on a pulling device. This sample is then pulled apart at a constant strain rate of 3 percent per minute until it fails at which point the strain at failure is recorded. The DTT test is done on 6 samples. Figure 180 shows the major DTT equipment.

Figure 180: DTT equipment.

Figure 180: DTT equipment.

Approximate Test Time

About 4 hours including sample preparation time.

Basic Procedure

- 1. Heat long term aged (PAV) asphalt binder until fluid to pour. During heating the sample should be covered and occasionally stirred to ensure homogeneity.

- 2. Pour the heated sample into two DTT molds (Figure 181), making sure to overpour so that there is excess along the top of the mold (Video 19). This overpouring will ensure enough asphalt binder to completely fill the mold. Sample preparation is critical and is the largest source of test variation.

- 3. Allow molds to cool for 30 – 60 minutes at room temperature, then trim the top of sample flush with mold using a hot spatula (Video 20).

- 4. To demold samples, cool mold in an ice bath or freezer at 23°F ( -5°C) for 5 to 10 minutes; just long enough that the beam can be easily removed from the mold without damaging it.

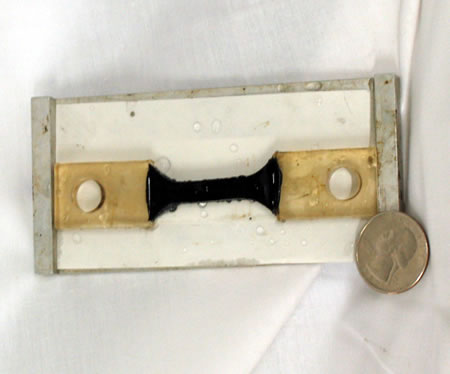

- 5. Mount the sample in the loading frame of the DTT (Figure 182). Match the holes on the end tabs of the sample with the loading pins on the load frame.

- 6. Remove the slack between the sample and the loading pins. Ideally this can be done automatically by the testing apparatus.

- 7. Start the test when the load reaches 0.45 lb (2 N). Set the strain rate to 3 percent/minute (this is often done automatically by the testing software).

- 8. Test a total of 6 samples as described in steps 1 through 7.

- 9. Failure identification. Failure of the sample can occur by two means: fracture (breaks apart in 2 pieces) or unrestrained flow without fracture. In the case of fracture, failure strain is defined as the strain at the moment of fracture. in the case of flow without fracture, failure strain is defined as the strain corresponding to the maximum stress observed. The test should not be continued past 10 percent strain; if the sample has not failed by 10 percent strain, record failure strain as “greater than 10 percent”.

- 10. Failure location. Ideally failure should occur in the gage section (the 18 mm long section of constant cross-sectional area). If failure occurs in the throat section, note and record this occurrence. The location of failure and its repeatability is highly dependent on sample preparation, straightness and proper mounting.

Heating time should be minimized to avoid oxidative hardening and volatile loss that will further harden the sample. (AASHTO, 2000c[2]).

Figure 181: DTT molds assembled (left) and disassembled (middle and

right).

Figure 181: DTT molds assembled (left) and disassembled (middle and

right).

Testing should be done as quickly as possible to minimize the effect of steric hardening that occurs during the test. Steric hardening can increase asphalt binder stiffness.

Do not quench (quick or rapid cooling) the samples to assist cooling.

Excessive cooling may cause unwanted hardening of the beam, which could cause increased test data variability (AASHTO, 2000c[2]).

Figure 182: Mounted sample.

Figure 182: Mounted sample.

四、 Results

Parameters Measured

- 1. Failure stress.

- 2. Failure strain.

The rate of elongation and peak load are also reported.

Specifications

The performance graded asphalt binder specification involving the BBR is:

- AASHTO PP 42: Determination of Low-Temperature Performance Grade (PG) of Asphalt Binders

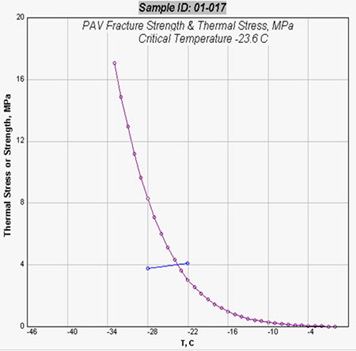

This procedure combines BBR and DTT test results to determine the low temperature asphalt binder grade by the following steps:

- 1. Calculate the stiffness master curve from BBR test data.

- 2. Create the creep compliance curve by taking the inverse of the stiffness master curve.

- 3. Convert the creep compliance curve to a relaxation modulus. This is a fairly involved and numerically complex conversion.

- 4. Calculate the thermal stress. This is also a fairly involved and numerically complex conversion.

- 5. Multiply the calculated thermal stress by a “pavement constant” (chosen through research as 18). This pavement constant converts the laboratory-determined thermal stress to an equivalent field cracking temperature.

- 6. Compare this calculated thermal stress to the failure stress from the DTT.

- ○ When initially grading an asphalt binder, two DTT test temperatures are used and a curve is drawn between these two temperatures (with just two points the curve is really just a line). The point at which this DTT curve intersects the BBR thermally induced stress curve (Figure 8) is defined as the critical cracking temperature of a pavement that uses the tested asphalt binder.

- ○ When prequalifying an asphalt binder for a specific PG grade, only one DDT test temperature is needed. If the DTT determined failure stress is above the BBR thermally induced stress curve then the binder passes the low temperature prequalification.

Figure 183 shows an actual plot of this data.

Figure 183: Plot of thermal stress vs. DTT results.

Figure 183: Plot of thermal stress vs. DTT results.

Superceeded Specifications

This section shows the original performance graded asphalt binder specifications for the DTT. These specifications have been superceded.

| Material of concern | Value | Specification | HMA Distress |

|---|---|---|---|

| PAV residue | Failure strain | ≥ 1.0% at 1.0 mm/min (0.039 inch/min) | Low temperature cracking |

Typical Values

Figure 184 shows a typical DTT output graph.

Figure 184: Typical DTT graph output.

Figure 184: Typical DTT graph output.

Calculations (Interactive Equation)

DTT software performs the necessary calculations automatically. The DTT software uses the following equations:

Failure Stress

Where:

- σf = failure stress (MPa)

- Pf = failure load (N)

- A = Original cross-sectional area (m2)

Failure Strain

Where:

- εf = failure strain (mm/mm)

- δf = elongation at failure (mm)

- Le = effective gage length (mm)